Today we present you the successful case of Euroma Group, specialized in components production for industrial automation and machine tools since 1979. The case study shows how the ability to design customized solutions was decisive to achieve the winning answers for one of the USA world’s leader in bicycles production.

What was the challenging request that the customer made to Euroma Group?

This manufacturer bicycles’ fame (made in USA) is due to the product research and obsessive attention to detail. This passion for details care pushed the US bicycle manufacturer to:

- Improve the accuracy of his work;

- Increase the productivity

N.B. Until then, the company was working the components that we are analyzing with pneumatic drills.

Which were the main problems to solve?

The main problems that Euroma had to solve were:

- To reach the customer required level of precision (far superior to that obtained from the air/ pneumatic system);

- To ensure the repeatability of the accuracy achieved on an increased production volume;

- Allow a quick and easy maintenance, reducing to a minimum the machines downtime;

- Ensure installation and rapid integration into the customer production processes.

Which was, then, the solutions that you suggested and what factors allowed Euroma Group to get the job?

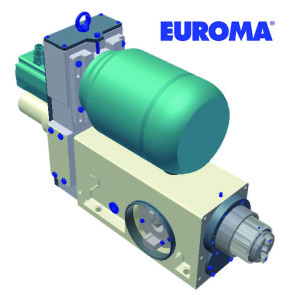

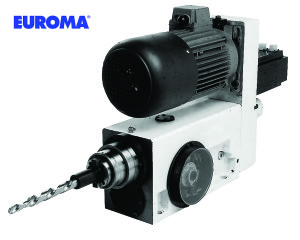

Euroma Group realized a solution to automate the production process using a programmable NC unit, suggesting the model F.CN24.120. This type of unit particularly suits the kind of work in which an easy managing is required and allows to operate in any position thanks to its references. Further winning features of the equipment are:

- Spindle drive = rolled, precision 16 mm dia. 25 x 5 mm pitch ball screw, pre-loaded to “0” back lash;

- Toothed belt drive = 1:1 (or otherwise) ratio, and Brushless motor mounting provision;

- Quill position limit switches = n°1 forward, n°1 at rest, n°1 “0” point.

The operating unit F.C. N 24,120, driven by rolled screw ball, allowes a repeatable and precise advancement thanks to Numerical Control system integration.

Euroma also guaranteed constant assistance onsite during all the installation and testing stages of the proposed solutions in the customer production lines.

What advantages has the customer obtained by giving the job to Euroma Group?

The solution developed by Euroma guaranteed to the customer the following benefits:

- Cost reduction due to the easy installation and maintenance of Euroma Group NC operating units compared to all the previously adopted solutions;

- Significant improvement of the machining accuracy and therefore of the components quality in output;

- Increase of the system productivity.

In general, what are the distinctive characteristics of Euroma Group?

First of all, when we talk about EUROMA GROUP we identify a brand that brings together three different brands:

1. Euroma, historic brand:

- Rotary Tables;

- Quill operating units;

- Spindle units motor spindles;

2. CMT Special equipment;

- “Soft clamping” automatic chucks

- Diaphragm chuck

3. ISA fork, angular, orthogonal heads and extension heads.

Summarizing, what are the main strengths of Euroma Group?

- Behind innovation: we always keep in mind the customer needs and provide the best solution for every single case;

- More than 35 years of experience in the production of components for automation and machine tools on customer request.

Have you got a similar problem to solve? Contact Euroma Group or visit Euroma at

EMO trade show

5-10 October 2015, Milan

Pavillon 7, booth F08